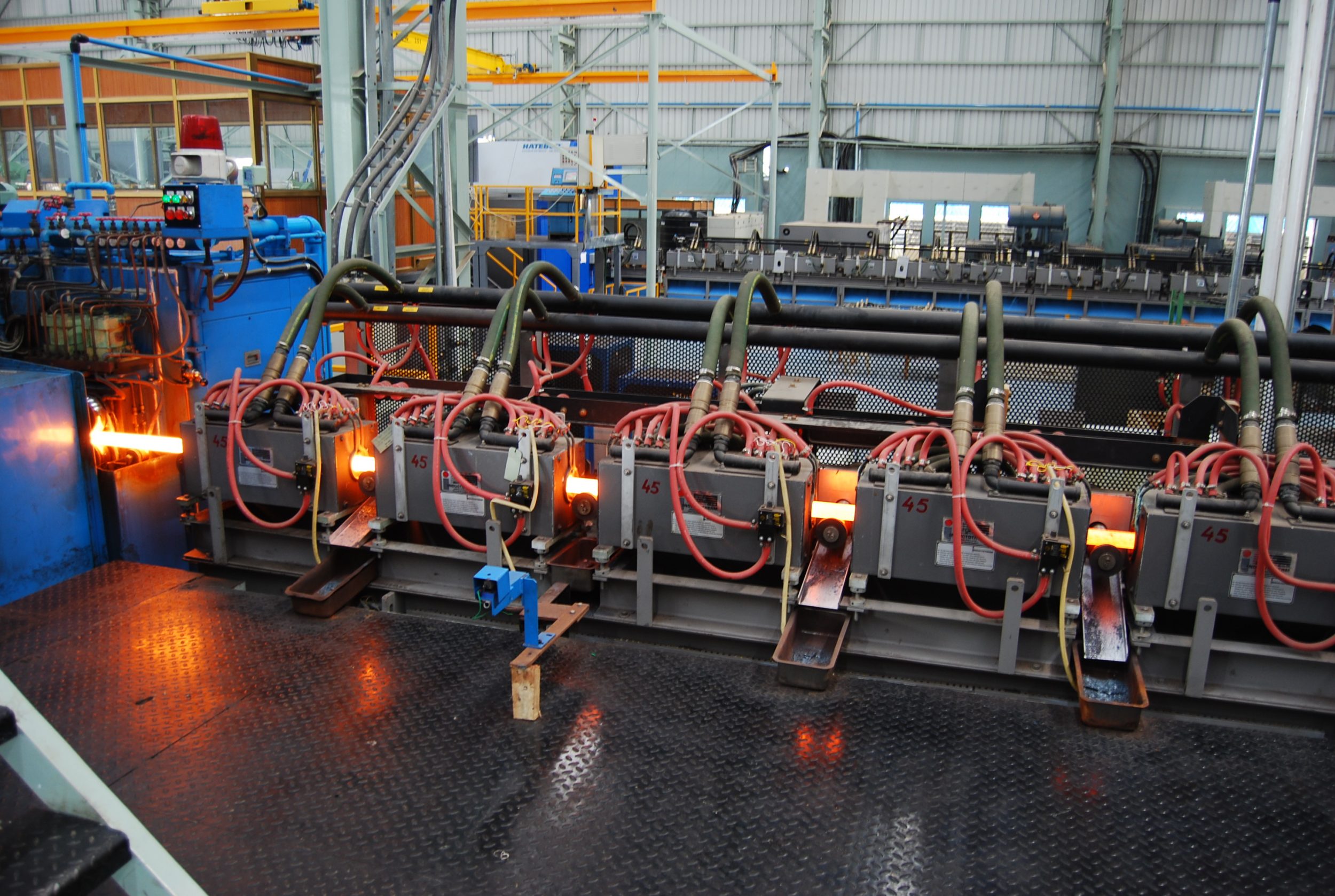

Inductoforge® Induction Bar Heating Systems for Forging

Induction bar heating systems for forging allow modern day forge shops to quickly heat up continuous bar media ensuring uniform temperature and unmatched efficiency. The Inductoforge® Modular Bar Heating System is flexible and allows the forge shop to assemble an induction system that exactly matches its application requirements. The powerful combination of advanced engineering, product innovation and over 55 years of experience in induction heating has made Inductoforge® the world leader in bar heating for forging.

Features

The Inductoforge® Modular Bar Heating System offers flexibility and efficiency with its individually controlled (500Hz – 6000Hz) power modules. The Inductoforge® heating systems utilize our proprietary iHaz™ Temperature Profile Modeling Software giving the user the tools to generate an ideal system recipe and precisely heated billet.

The iHaz™ software package is a predictive numerical simulation technology that accurately forecasts the temperature throughout the cross section of the billet, from the surface to the core. The heating system’s modular design makes it possible to employ a standby function that keeps the billet at temperature, ready to start forging immediately following minor line disruptions.

- Eliminates heating recipe guesswork

- Optimal system efficiency

- Unmatched temperature uniformity

- The industry’s most advanced heating technology

- Modular design permits standby functionality (hot parts ready immediately following minor line disruptions)

- High energy efficiency

- Enhanced productivity

- Optimum forging temperature

Tech Specs

| Power Output | 300 kW – 10 MW | ||||

| Bar Diameters | 3/4″- 10″ | ||||

| Applications | Heating for forging, rolling, warm forming and extrusion | ||||

| Misc. | Continuous casting boost heaters for steel, stainless steel, aluminum and other materials. •Heaters for specialty alloys and titanium. | ||||

| Production Rates and Coil Sizes | Part Size | Rate | kW Size | Frequency | # Coils |

| 0.55-1.02″ (14-26mm ) | 3682 lbs (1,670kg)/hr | (1) 750kW | 5.2kHz | 2 | |

| 0.74-1.73″ (19-44mm) | 8245 lbs (3,740kg)/hr | (1) 1500kW | 3kHz | 4 | |

| 0.74-1.73″ (19-44mm) | 11,740 lbs(5,325kg)/hr | (1) 2000kW | 3kHz | 5 | |

| 1.10-2.16″ (28-55mm) | 15,432 lbs (7,000kg/hr) | (1) 2400kW | 2kHz | 8 | |

| .70-1.77″ (18-45mm) | 19,841 lbs (9,000kg)/hr | (1) 2400kW (1) 800kW | 2kHz 5.2kHz | 14 | |

| 1.41-2.99″ (36-76mm) | 30,865 lbs (14,000kg)/hr | (2) 2500kW | 1kHz | 14 | |

| 1.41-2.99″ (36-76mm) | 39,683 lbs (18,000kg)/hr | (1) 3500kW (1) 3000kW | 1kHz | 14 | |

| 1.41-2.99″ (36-76mm) | 46,297 lbs (21,000kg)/hr | (2) 4000kW | 1kHz | 20 | |

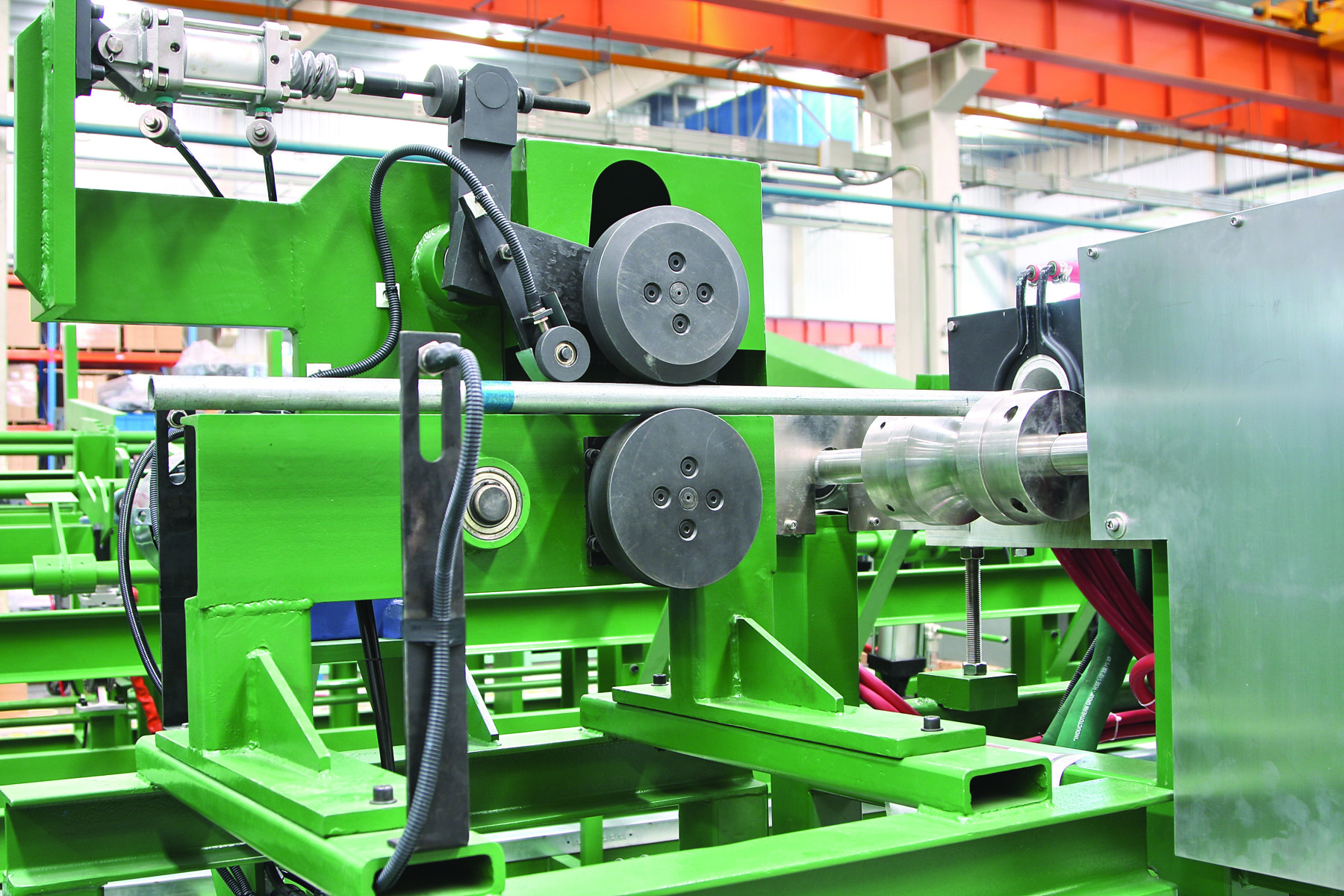

Accessories

- iHaz™ temperature control modeling software

- Bar loader and storage system (Bar rack/sling)

- Coil Shuttle

- iHAZ™ Advanced temperature control

- Standby

- Bar Cooldown Table