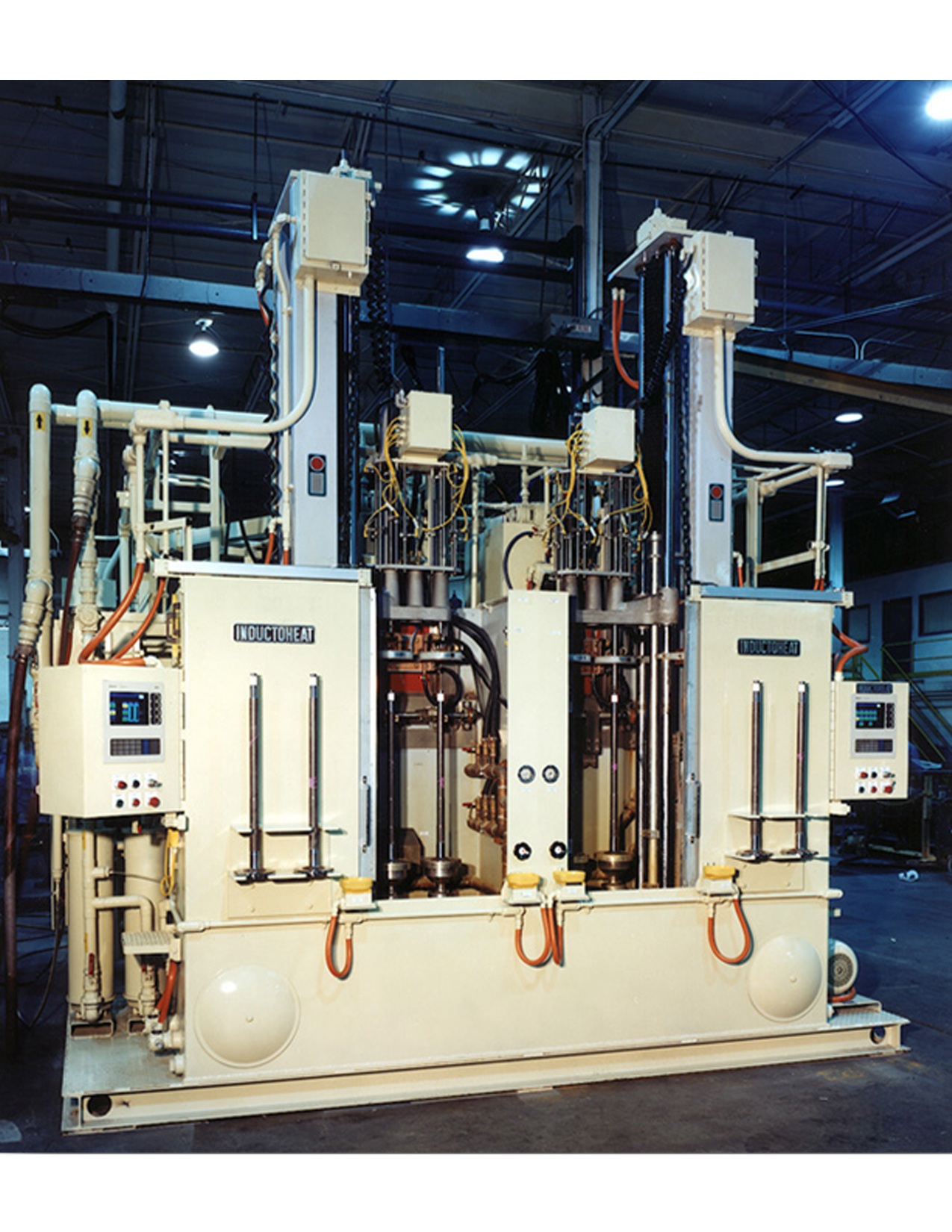

VSM95 Modular Induction Heat Treating Scanning System

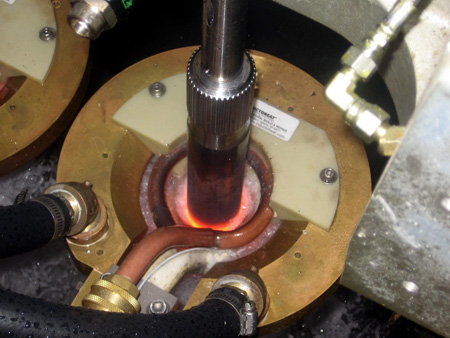

The Inductoscan® VSM95 Induction Heat Treating Scanning System is ruggedly designed for high-volume scan hardening of most cylindrical parts up to 400 lbs. and as long as 80 in. It can be customized to perform various heat treating operations such as; scan, single-shot, lift/rotate and linear transfer.

Features

- One, two or four-spindle, vertical-scanning precision induction hardening machine

- PLC control with video display terminal for operator interface which, includes DC SERVO drive and motor

- User friendly controls simplify set-up, changeover and trouble-shooting, includes PLC with industrial computer operator interface

- Inductor ground sensor. Travel limits. Heavy-duty aluminum splash door with safety switch

- Enclosed water cooling and quench recirculation system with filtration for quieter operation

- Scanning speeds are user-selectable from 0.01 in./sec – 8.0 in./sec (1 mm/sec – 200 mm/sec)

Tech Specs

| Standard Power Ratings | 135 kW-200 kHz, 150 kW-3/10 kHz, 200 kW-3/10 kHz, 300 kW-3/10 kHz | |

| Dimensions | 79″ W (2000 mm) 68″ D. (1700 mm) | |

| Tower Scan Length | 40″ (1016 mm) / 60″ (1524 mm) / 70″ (1778 mm) | |

| Maximum Part Length | 50″. (1270 mm) | |

| Scanning Speed (Max)/sec | 0.04-8.0 in./sec. (.1-203 mm/sec) | |

| Door Dimensions | 31.5” (800 mm) W X 68” (1727 mm) H | |

| Work piece Capacity/Spindle | Models available to scan part lengths in 10 in. (250 mm) increments from 30 in. (760 mm) to 80 in. (2030 mm) depending on tower size. | |

| Spindle Center Spacing | Standard models available for maximum part lengths in 10 in. (250 mm) increments from 34 in. (860 mm) up to 84 in. (2130 mm) depending on model. | |

| Workpiece Capacity/Spindle | 300 lbs. (135 kg) on single spindle or 400 lbs. (180 kg) max. total. | |

| Height Tower Up | 92.75 in. (2,400 mm) | |

| Height Tower Down | 81.50 in. (2,100 mm) | |

| Standard Controls | Standard PLC with HMI interface with virtually unlimited program recipe storage | |

| Cooling system | Closed-loop water recirculating systems with stainless steel tank, stainless steel plate heat exchanger, non-ferrous pump and plumbing | |

Accessories

- Instachange coil adapter

- Servo motor and gearbox driven ball screw

- Process monitoring signature package

- Process data archiving

- Pneumatic door

- Pneumatic load assist vees

- Pneumatic upper centers

- Automatic lubrication system

- Quench filtration upgrade

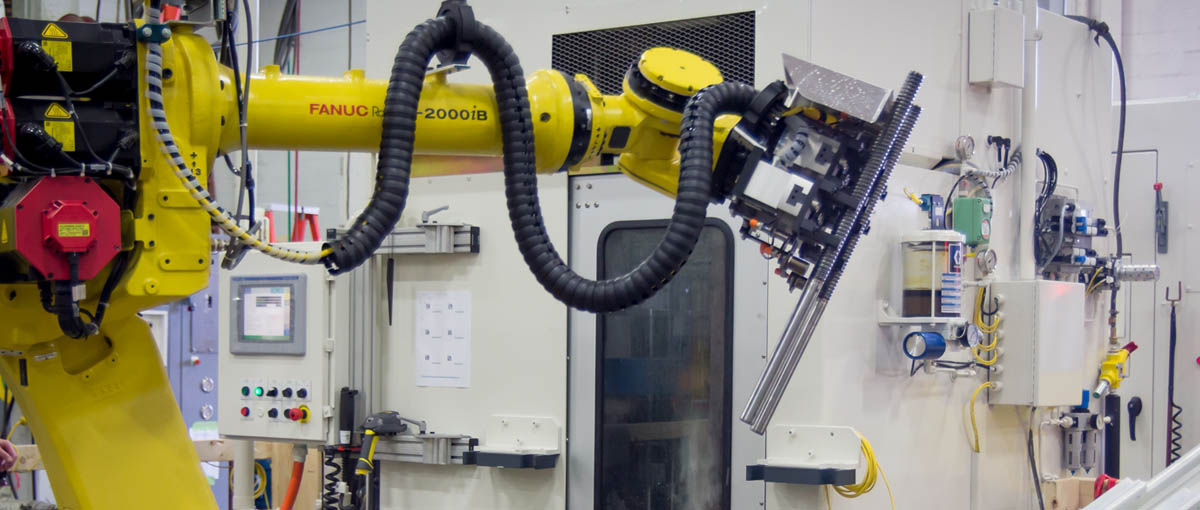

- Robotic interlock package

- 6 Axis 20kg robot