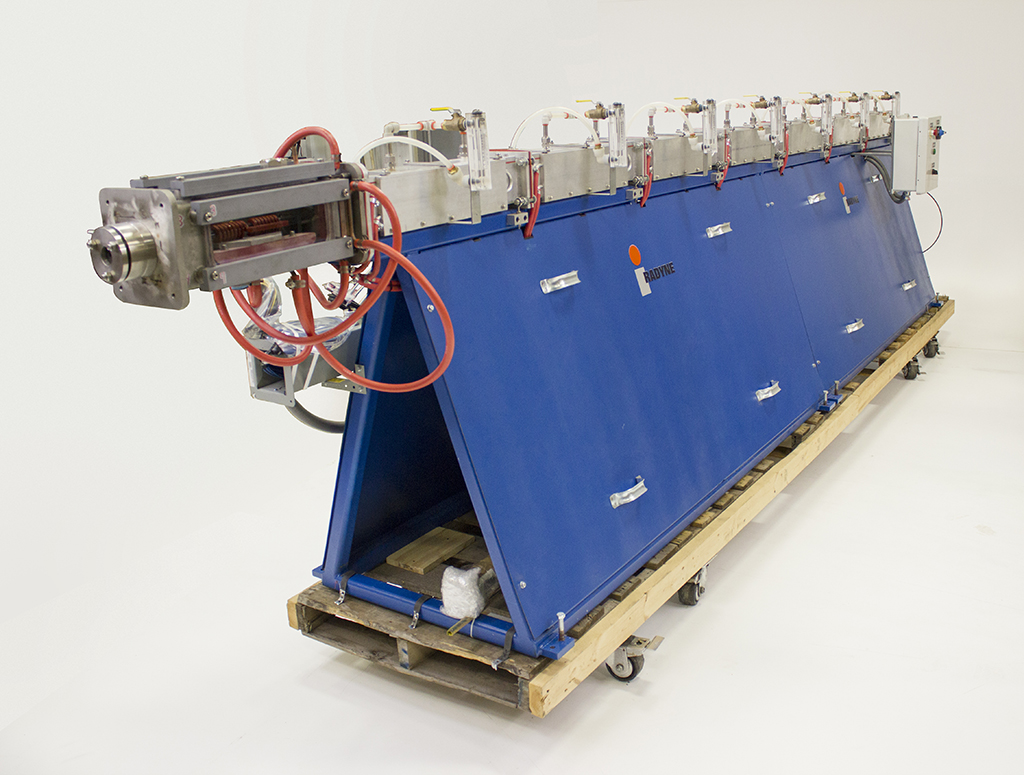

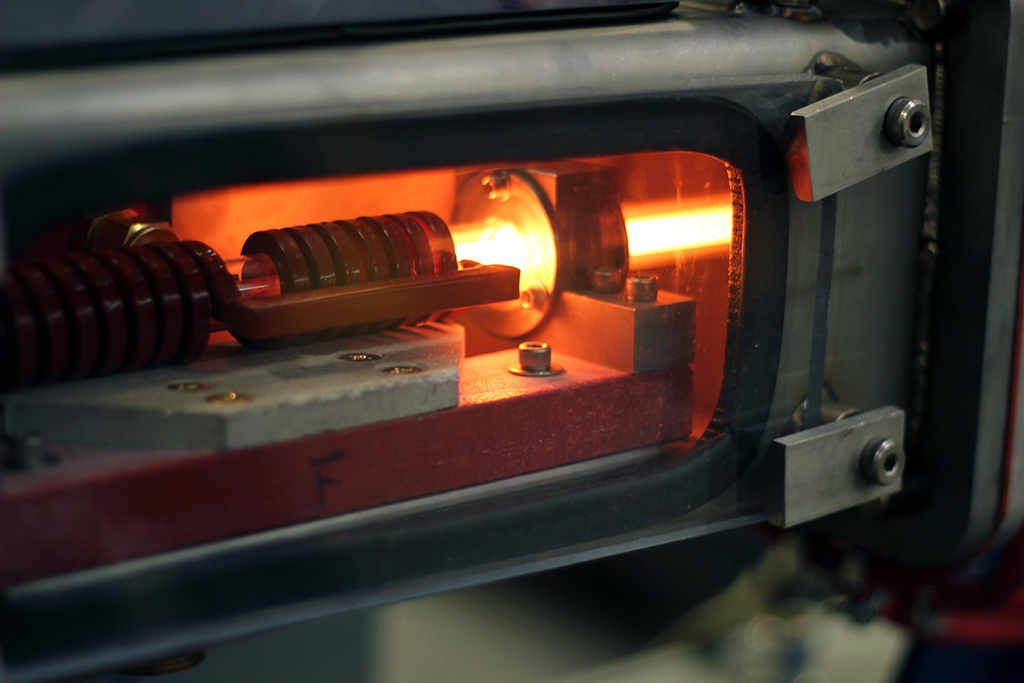

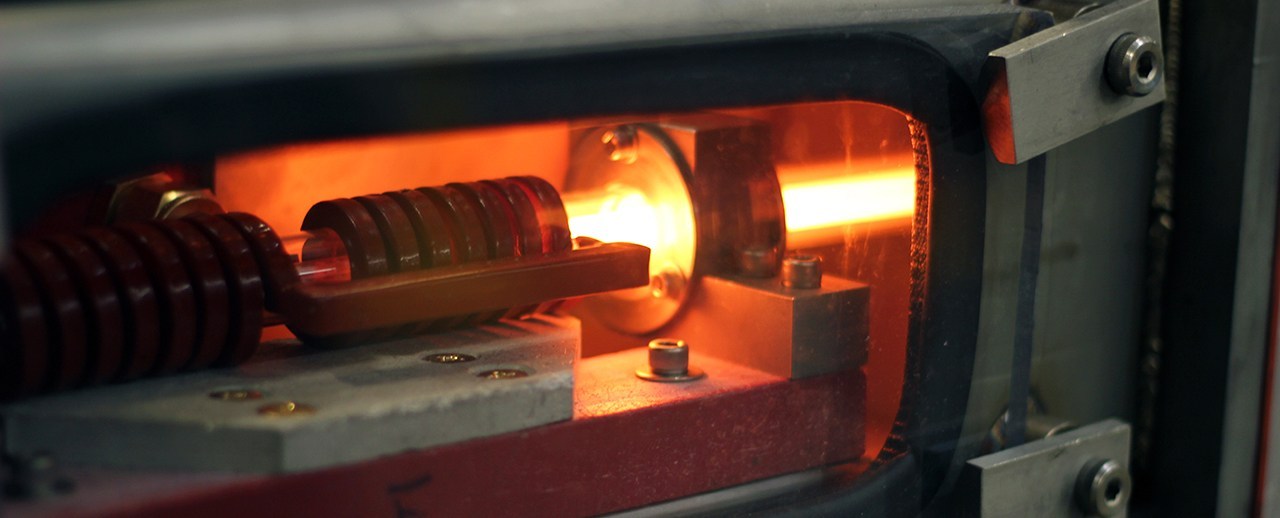

Tube Bright Annealing Line

Radyne’s Tube Bright Annealing Line fits directly in-line with today’s high-speed drawing and welding lines or can be ordered with payoff, straighteners, drives, controls and take up for reel to reel offline processing, making them the preferred choice for lean, agile manufacturing. Utilizing a modular and expandable design, Radyne’s Tube Bright Annealing Systems meet virtually any line speed, product dimension, or material- supporting oxygen-free copper, brass, titanium, stainless steel, nickel, and more.

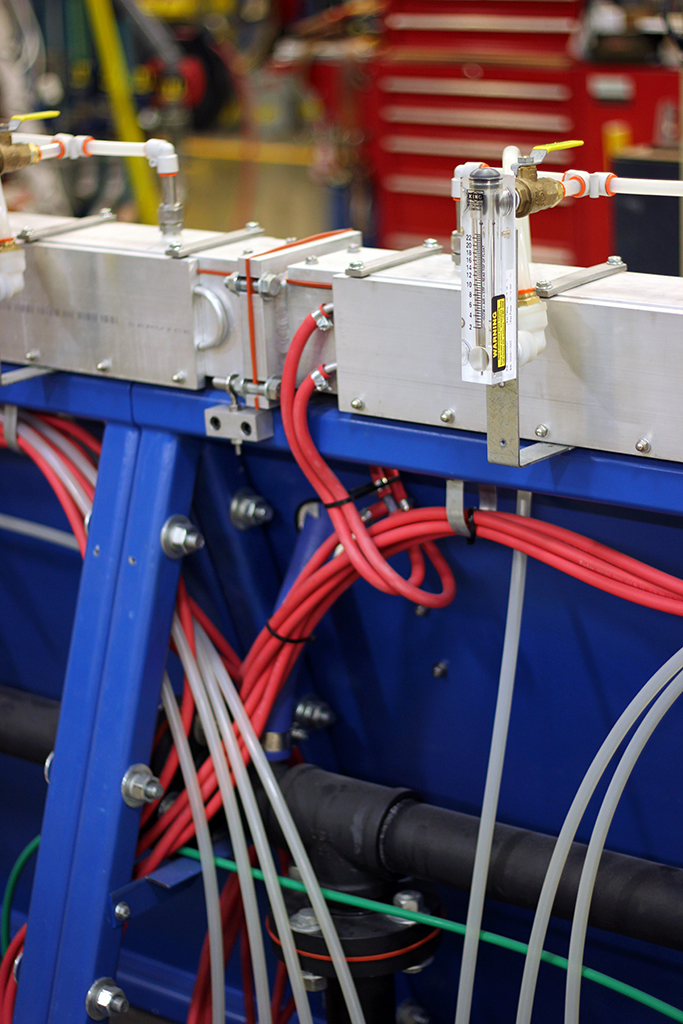

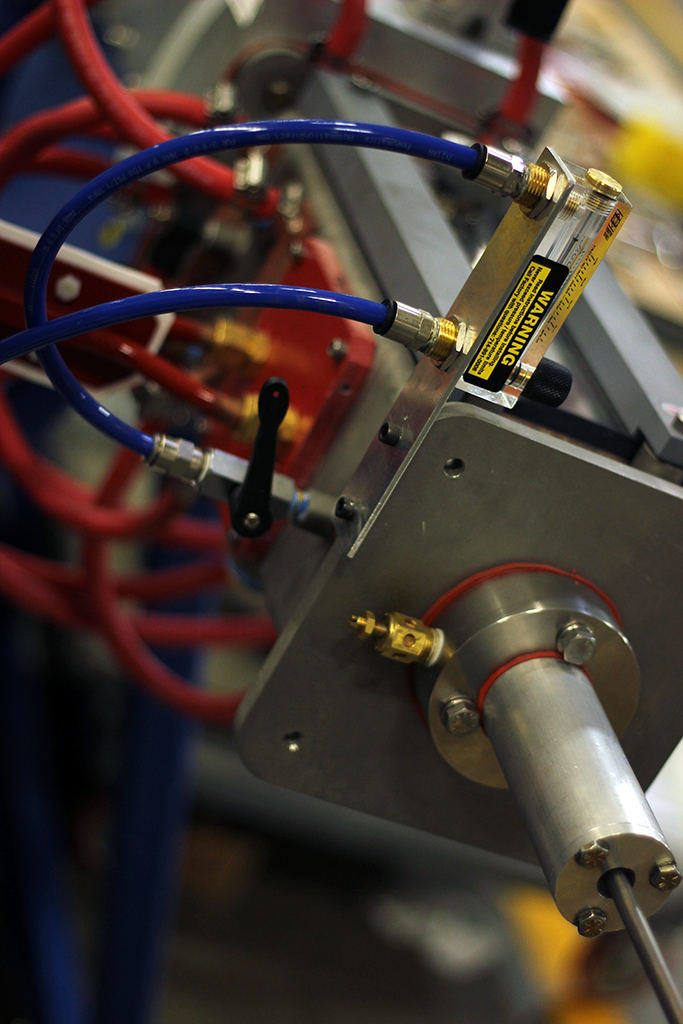

Quench/Controlled Atmosphere Containment Details:

- Contained Atmospheres – Nitrogen, Nitrogen with up to 4% Hydrogen, Argon, Argon with Hydrogen

- Carbon Contact or Optional inert gas quench available

- Save money with Optional gas recycling

- Control the environment with precision with optional gas manufacturing and mixing control and sensing subsystems

- Gas Impingement Quench – Finished, high quality surface

Features

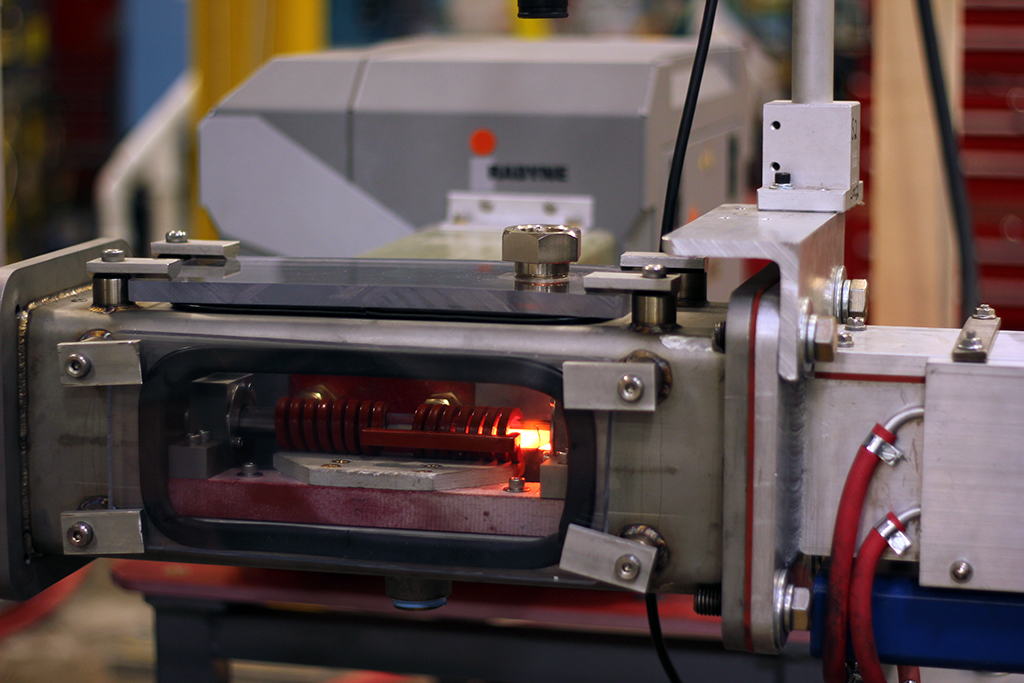

The Tube Bright Annealing System’s Innovative design allows for easy changeover between various diameter product, and each system is equipped with precision automatic power control.

- Designed for ease of operation and maintenance

- Automatic speed sensor controls power proportionate to line speed

- Recipe storage and retrieval

- Integrated temperature sensing

- High wear ceramic tube guides

- Integrated pumping system

- Solid state inverters

Tech Specs

| Bright Annealing Tube System | ||

| Size | 2 mm – 63 mm tube | |

| Speed | 100 ft./min [30 m/min] | |