Low Frequency Heating Systems

IROSS™ Line Frequency Systems provide unique benefits over other types of induction heating units. Because the IROSS™ systems use low frequency induction (60hZ), they can be used to heat large and irregularly shaped workpieces for a variety of applications. These systems are generally used to achieve temperatures of 120 to 1600 Fahrenheit within a short amount of time, which makes it an attractive alternative to furnace/oven heating. Utilizing a low frequency allows for the heating of a large area as the depth of penetration depth is greater than that of a higher frequency induction system.

Some applications include:

- Shrink fitting

- Mold preheating

- Stress relieving

- Curing of rubber

- Varnish curing

- Magnet bonding

- Tempering

- Annealing

- Pipe-end annealing

- Pressure vessel heating

- Preheat for welding

- Removal of coatings

- Lamination preheat for die casting & bluing

- Friction weld and swage stress relieving

- Shrink fitting for shafts & gears

- Motor housing disassembly

- Bonding of rubber to metal

Some Automotive applications include:

- Camshaft gear assembly

- Crankshaft gear assembly

- Starter ring gear assembly

- Vibration damper bonding

- Transmission gear assembly

- Timing ring assembly

- Crankshaft flange assembly

- Steering knuckle assembly

- Shrink fitting of Large /Heavy-truck Differential Gears

Tech Specs

| Standard Power Ratings (Other sizes available upon request) | 25, 50 and 75 kVA, 50/60 Hz, single phase |

| Machine Dimensions (W x D x H) | 32” x 42” x 72” (800mm x 1060mm x 1820mm) |

| Available Mechanical Modules | Part Lift, Part Lower, Coil Lower, Stationary |

Accessories

- Infrared temperature control

- Energy monitor

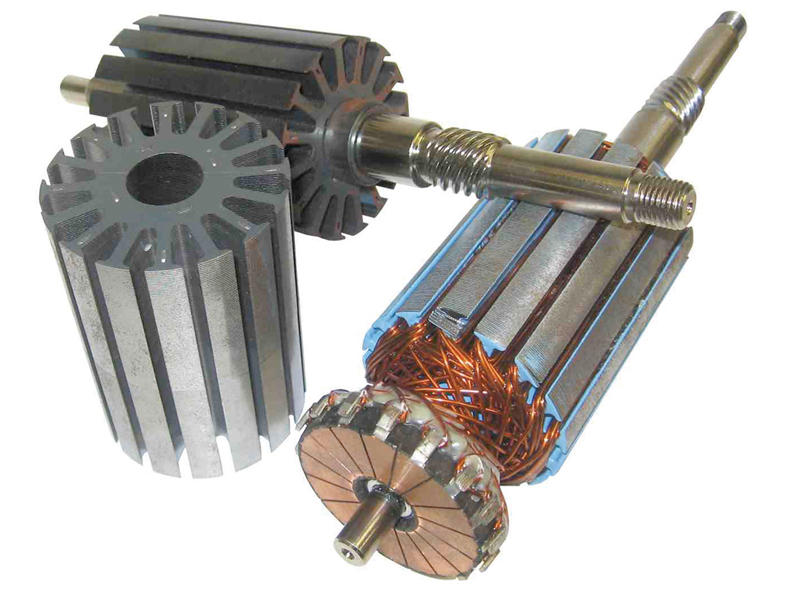

- Custom tooling for armatures, rotors, stators, motor housings, permanent magnet motor bonding, gears and bearings

- Other mechanical system modules available.