Vertical Steel Induction Billet Heating

Banyard Vertical Steel Induction (VSI) Billet Heating systems are designed for precision heating of billets made from steels and other alloys prior to extrusion.

Banyard engineers have responded to the challenge of uniformly heating billets for the steel extrusion process, applying over 40 years design and manufacturing experience gained from specialist induction heating applications. As a world leader in the design and manufacture of Low Frequency Induction (LFi) power supplies, Banyard also offers customers extensive electrical control and mechanical handling expertise, delivering turnkey solutions.

The result is Vertical Steel Induction Billet Heating systems (VSI) , offering the latest in proven technology whilst delivering fast, accurate and highly repeatable induction heating of steel billets. Banyard turnkey Vertical Steel Induction Billet Heating systems offer customers total reliability and low maintenance costs prior to the extrusion process.

Banyard Vertical Steel Induction Billet Heating systems are designed for precision vertical induction heating of solid or pierced billets and tubes with diameters over the typical range 150 mm to 460 mm, and lengths between 300 mm and 1500 mm. Full systems include multiple heating stations to give the overall system throughput to meet the demands of the extrusion press.

Features

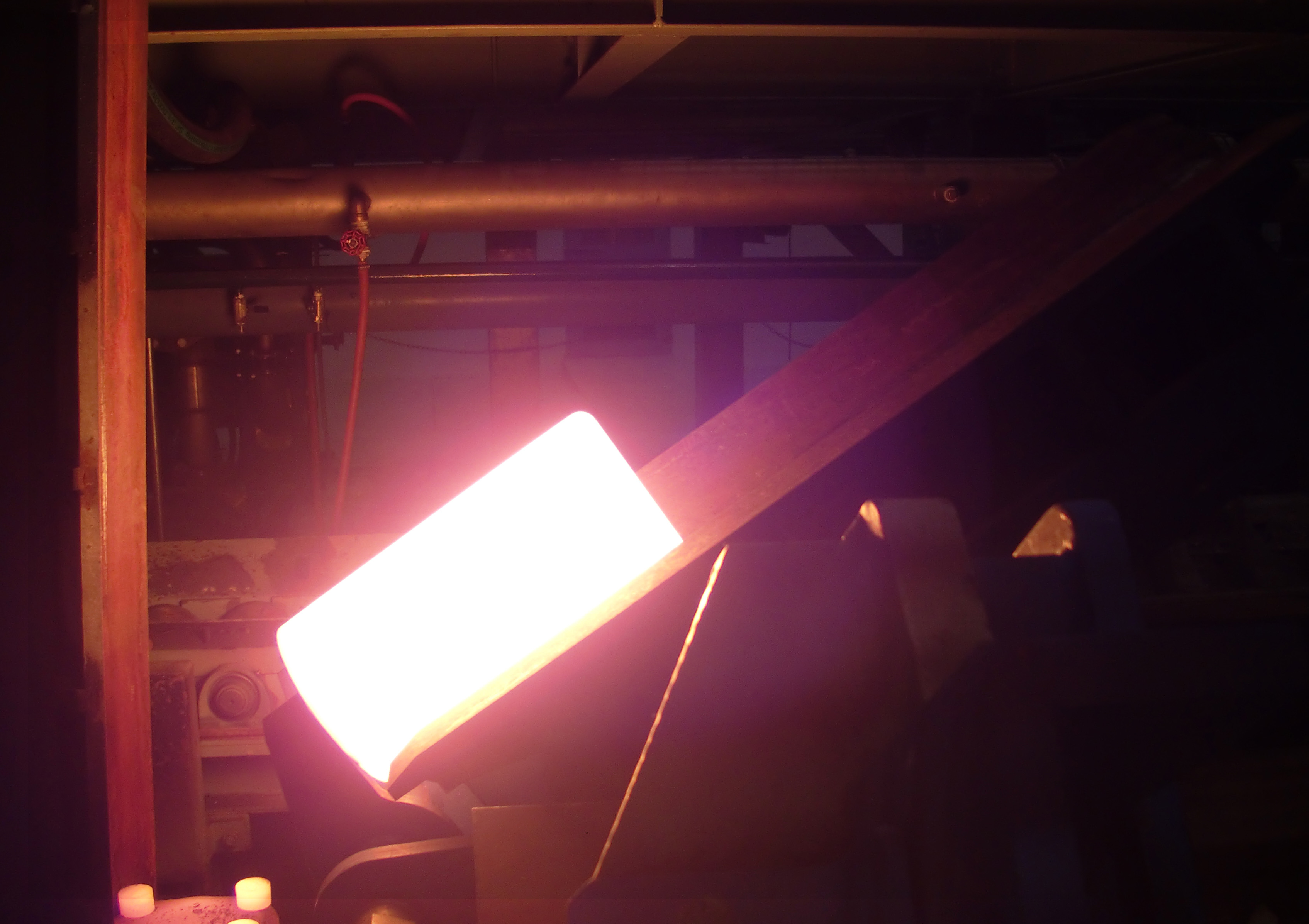

Induction Coil & Power Converter

Each heating station includes a low frequency power converter set of induction coils configured to the needs of the customer. Closed loop multi-zone control enabled billets to be uniformly heated even when the initial temperature uniformity is poor as a result

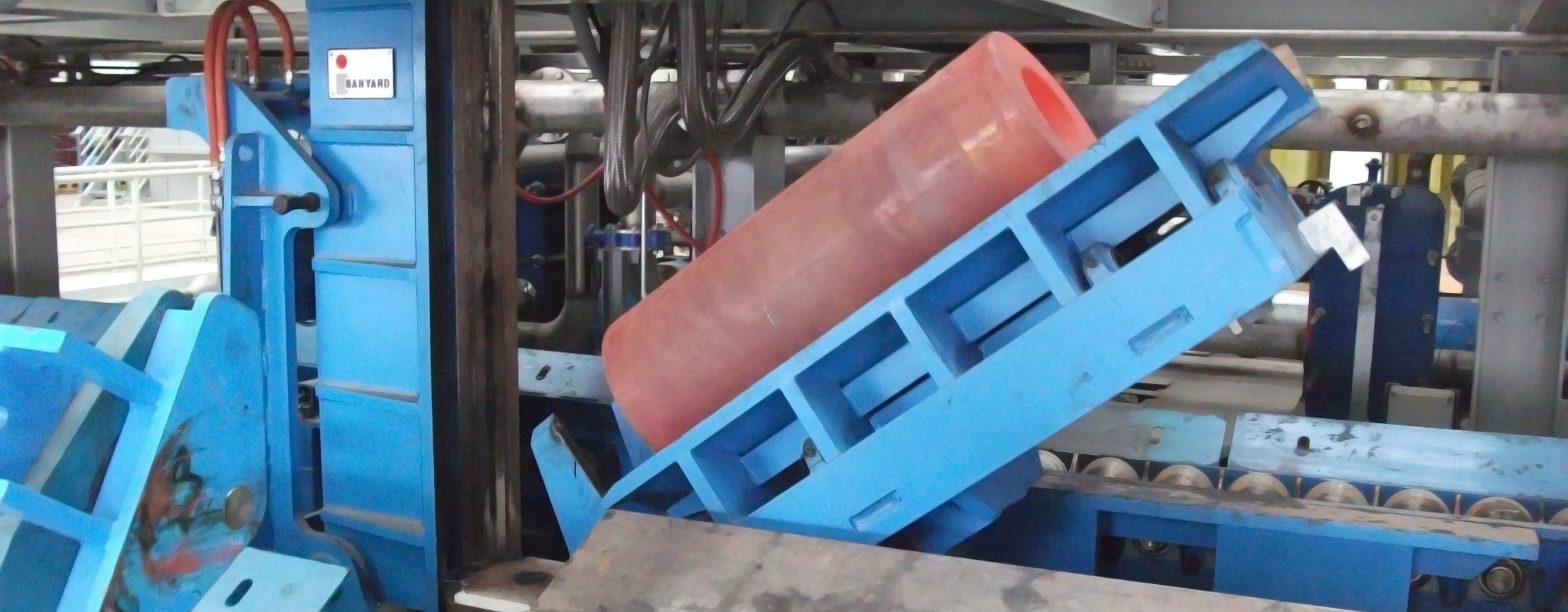

Billet Up-Ender / Charger Unit

Pre-heated billets are discharged sideways to the heating station up-ending units by pusher to a transfer ramp from the cold billet shuttle conveyor. The transfer ramp holds the billet, awaiting the control signal for the billet heating to commence. The transfer ramp then loads the billet into the up-ender. This orientates the billet in a vertical mode and inserts it into the vertical induction coil via a hydraulic lifting ram. The hot billet is then lowered and discharged sideways onto the hot billet trolley conveyor. An adjustable lifting ram accommodates different billet sizes.

PLC System and Operator Interface

A standard PLC control system is provided based upon Siemens S7 series components for the control and sequencing of all induction heaters (pre-piercing, and pre-extrusion), conveyors and up-ending / charging units. The system includes SCADA for data logging and recipe management.

The system includes distributed I/O at the individual heating stations and an operator console which can be located at the press operator’s position. The operator’s terminal includes an HMI panel for entry of production parameters and system status display.

Minimising Oxidation (Scale)

The induction coils include a top hat assembly mounted on top of the coil to significantly reduce convective heat loss and to provide containment for controlled atmosphere heating of carbon steels.

Inert gas ports are provided at the base of the coil to allow for a controlled atmosphere inside of the induction coil. When combined with reduced heating times this results in significantly less oxidation and scale formation when compared to traditional oven heating.

Benefits of VSI technology

- High circumferential temperature accuracy and repeatability. i.e. better temperature distribution.

- Automated coil tap variations for different billet lengths giving the ability to vary the temperature profile along the billet length.

- Ability to process billets from different materials with minimum oxidation and scale (by controlled atmosphere technology).

- No billet sticking.

- No glass lubricant build-up.

- Flexibility of operation

- Single-zone systems with automated coil tap variations for different billet lengths giving the ability to vary the temperature profile along the billet length

- Multi-zone systems with zone control and switching for different billet lengths giving the ability to vary the temperature profile along the billet length

Tech Specs

- Temperature Considerations

- To ensure that temperature accuracy is linear along the length of the billet, specially designed laminated flux concentrators are positioned above and below every billet within the induction coil.

- The positions of these flux concentrators are relative to the billet, its position within the induction coil controls and the end temperature of the billet.

- Two optical pyrometers are provided to closely monitor the maximum surface temperature of the billet, providing a fail-to-safe temperature check policeman.

- Overall temperature repeatability of +/- 15⁰C can be achieved with point to point temperature guaranteed to be within 5%.

- Maximum surface temperature is always taken into account before determining the optimum applied power / heating curves for a specific billet size.

- Depth of heat penetration on billet surface increases at lower frequencies. To ensure maximum productivity and optimum operating conditions are achieved, the frequency can be varied.

Flexibility exists for raising the billet-end temperature in order to overcome radiation losses.

- VIP power inverter specifications

- Power rating: 500kW to 1000kW

- Supply: 400V 3-Phase, 575V 6-Phase (depending on power required)

- Power factor: 0.95 Efficiency >95%

- 0 to 100% step-less power control

- Adjustable frequency 50 to 150Hz